Kohler Power Systems, part of Kohler Energy, has collaborated with Toyota Motor North America (Toyota) to develop and install a hydrogen fuel cell power generation system at the Klickitat Valley Health hospital in Goldendale, Washington. The fuel cell power system combines Kohler and Toyota technologies to showcase the viability of the zero-emission technology for power generation. The system and upcoming installation marks a significant step for Kohler toward offering a commercially available product that will help customers with their decarbonization goals.

“Kohler is committed to investing in new technologies to help our customers achieve their resiliency goals without sacrificing their climate-related objectives, and fuel cells are a hugely promising opportunity – both on their own, and when combined with other complementary technologies for more flexible power strategies, such as microgrids,” said Charles Hunsucker, Kohler Power Systems President. “Kohler has a strong relationship with Toyota, and we greatly value its commitment to clean energy and its technological expertise in fuel cells.”

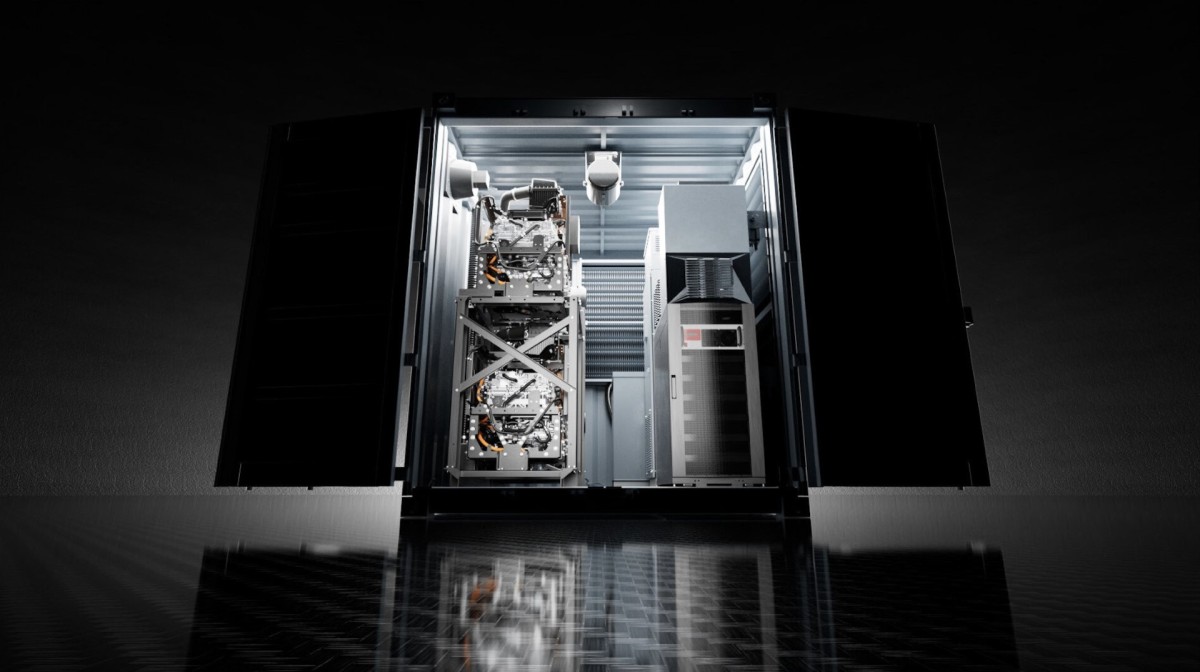

Merging Kohler’s energy management expertise with Toyota’s leading fuel cell technology, the fuel cell power system combines Kohler’s power generation control platform and system integration expertise with a fuel cell module from Toyota for a scalable, industry-leading solution for zero-emission power that can meet the diverse needs of a variety of customers. The resulting new “KOHLER Fuel Cell System” is ideal for prime, peak shaving, and emergency situations. The system can be scaled or customized by application to ensure the delivery of exceptional performance for the specific needs of customers, whether for individual installations or covering entire facility complexes.

“Toyota has been exploring various applications of our fuel cell technology and this opportunity with Kohler highlights the decarbonization opportunities that hydrogen as a fuel can provide for customers,” said Chris Yang, Group Vice President, Business Development, Toyota. “Our fuel cell technology can be scaled and used to power a wide variety of products beyond transportation, and it does so without any emissions except water.”

The first KOHLER Fuel Cell System will be installed at Klickitat Valley Health, a hospital that serves as the principle medical center for over 10,000 people in their district. The hospital previously announced plans to reinforce their electrical infrastructure including backup and secondary power generation that included a hydrogen fuel cell to ensure uninterrupted operations. The Kohler system will be used to support their power strategy, helping the hospital to meet its preparedness needs.

Launching the KOHLER Fuel Cell System is a significant milestone in Kohler’s commitment to sustainability. This initiative aligns with our mission to improve the company’s operational environmental footprint while designing more environmentally friendly products that help our customers and consumers in their own sustainable journey. Kohler has been tracking its environmental footprint since 2008 as a key part of its environmental strategy, and it has established goals for reducing Scope 1-2 GHG emissions, water usage, and waste to landfill across its operations.

KOHLER Controls and System Integration

Leveraging decades of experience in energy systems, a Kohler-designed and manufactured controller will continuously monitor and manage operating conditions to harness the reliability, flexibility, and performance of the Toyota fuel cell as well as protect it from damage. The control system is extremely versatile and customizable, so Kohler can provide a system that functions precisely as the customer expects and interoperates with building-management systems (BMS).

Kohler will also complete the system integration and balance of plant to ensure all supporting components and auxiliary systems needed to deliver energy operate together safely and reliably and within a turnkey package.

TOYOTA Fuel Cell Module

In response to increasing demand for clean power generation across several industries and applications, Toyota has consolidated various components from a second-generation Toyota Mirai passenger vehicle fuel cell system into a single, compact fuel cell module. The newly created module includes the second generation’s improved fuel cell stack and the elements responsible for the generation of electricity (air containing oxygen and the gaseous hydrogen fuel), system cooling, and on-board power control. The module can be easily integrated and scaled into a variety of power plant applications.

Toyota has more than 30 years of experience in fuel cell (FC) technology development and has worked to advance the creation of a hydrogen society that includes a focus on clean transportation. To date, Toyota has already developed and sells the hydrogen-powered Mirai fuel cell electric vehicle and has collaborated to scale the technology to create larger powertrain kits for things like heavy-duty class 8 trucks. The scalability and familiarity to the operation of FC systems makes it quickly adaptable to various applications and industries.