Data centres and servers are vital infrastructure components, responsible for storing, communicating and transporting massive amounts of information generated daily. They play a key role in everything from facilitating modern conveniences to ensuring mission-critical data exchanges. Maintaining data centres and servers at peak performance is a top organisational priority to avoid the major disruption and costs associated with downtime.

Due to the power of modern data centres and servers, high-frequency electromagnetic interference (EMI) shielding requires careful and proactive management – a consideration more important than ever with today’s ultra-fast electronic systems. The latest data centres also feature an increasingly dense population of electronic sub-systems and components. These facilities are ‘alive’ with a myriad of signals that almost compete for attention. Interaction between signals is a primary cause of cross-talk and interference, which in turn can reduce the quality of electronic devices.

Too much noise

Interference is typically unintentional. As well as signal interaction between internal electronic components, EMI can emanate from a broad spectrum of natural and man-made sources, such as television/radio transmissions, solar magnetic storms, lightning, static electricity, power grid transmission lines, airport radar, mobile phones, factory machinery and switching-mode power supplies to list but a few.

Sometimes, however, interference is malicious. Saboteurs and other unscrupulous individuals can use directed EMI as opportunity to interfere with signals remotely. Whether the interference is intentional or not, EMI shielding is of paramount importance.

The effects of EMI can extend from inconvenient to disastrous – the latter in technologically busy areas like airports and hospitals. System administrators, network engineers and others who work directly with data centre equipment might notice anything from shaky monitor screens and communication errors, to compromised data integrity and even complete system failures where hard drives become scrambled or even wiped completely. Anyone observing a server with unexplained data errors that routine troubleshooting does not resolve should investigate potential sources of EMI.

As a general rule, high-powered devices are more likely to require a higher level of EMI shielding. They will also generate more heat, which can cause device or system failure without the right precautions.

Data centre system designers must find ways to evolve with emerging technologies and utilise products and solutions that can deliver optimal performance in these environments.

Seal of approval

To ensure adequate EMI shielding for servers and data centres, several types of high-performance electrically conductive gaskets are available. Selecting the optimal product for the application is critical.

Gaskets serve to seal any differences between surfaces, providing a complete low-impedance path for EMI signals by addressing all access, egress and ingress points. High frequencies from 100 MHz to 300 GHz are particularly sensitive to small gaps in surfaces.

Soft and flexible gaskets perform well in these instances. Anything too stiff could create gaps instead of preventing them in applications involving doors, lids or panels, for example. The enclosure will subsequently lose its ability to shield against EMI.

Material world

A common form of EMI shielding gasket is a non-conductive low-density foam surrounded by a conductive fabric wrapping (known as fabric-over-foam, or FoF). FoF provides a very economical solution for low-closure force electronic applications that require EMI shielding and electrical grounding.

By combining the conductive properties of an electrically conductive fabric and the conformability of a foam core, FoF gaskets ensure both high conductivity and high cycle reliability at an affordable price. FoF products also offer plenty of engineering flexibility and, importantly for data centres and servers, good protection against the ingress of dust.

Gaskets are available in strip form and a variety of catalogue and custom profiles comprising many foam/fabric combinations. A particular combination of benefit in data centre and server applications is a soft, open-cell urethane foam wrapped in a conductive nickel-plated copper polyester taffeta fabric. The result of this carefully engineered configuration is excellent compression set (15%) in low-closure force applications requiring high shielding effectiveness (>100 dB). Typical uses include server faceplates and blade cards.

Silver lining

Another economical EMI shielding option for data centres and servers is conductive foam. Although widely available, a certain proprietary conductive foam solution contains embedded silver-plated fibres rather than traditional conductive particles. Most conductive foams lose their integrity upon the addition of particles and subsequently fail to bounce back easily, resulting in poor compression set.

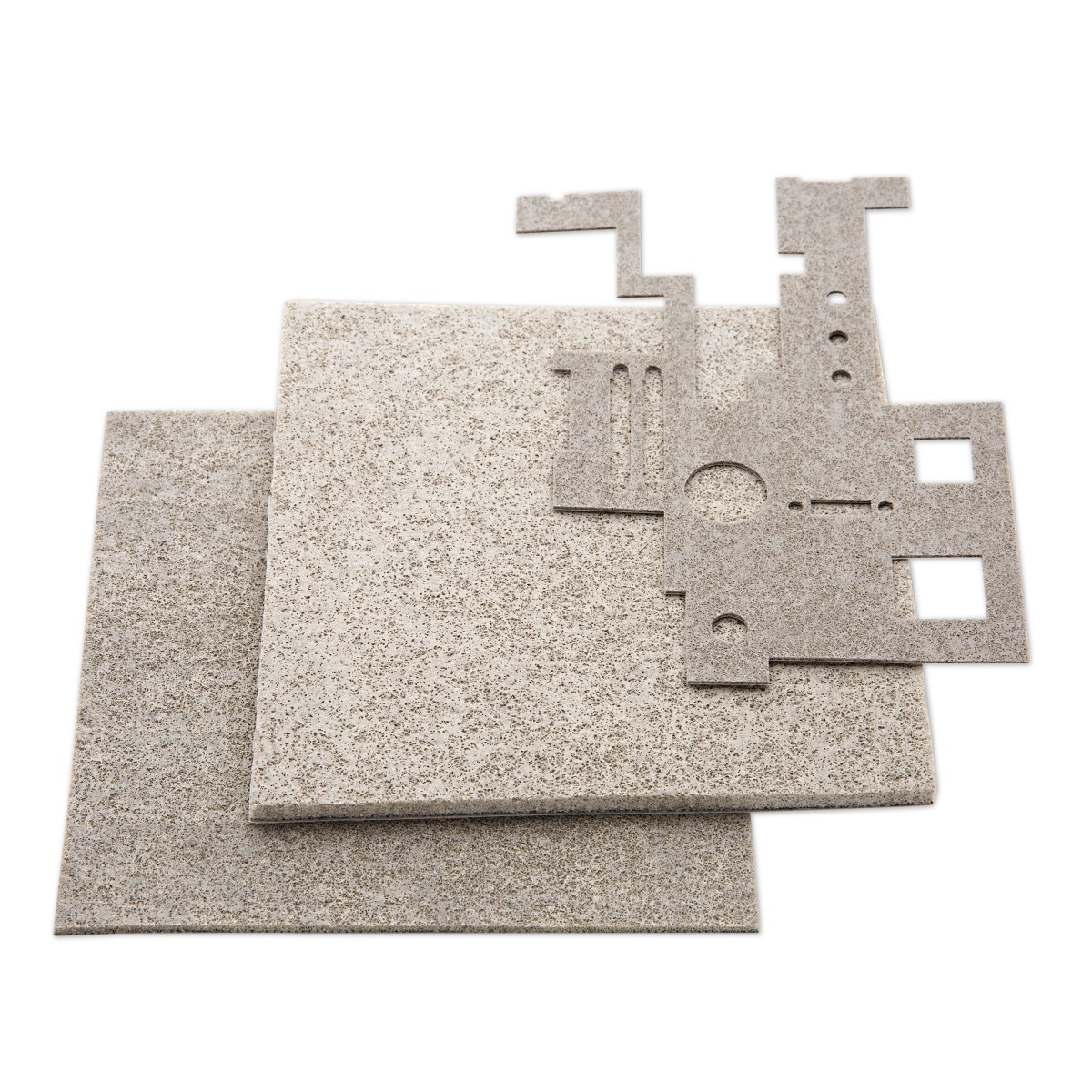

Instead of particles, conductive foams with silver fibres that run their entire length maintain contact from one side of the surface to the other. By embedding these silver-plated fibres into low-density, open-cell urethane foam, users benefit from stable electrical performance and superb conductivity with extremely short ground paths. This type of multiplanar, z-axis conductive foam also delivers great design flexibility, coming in sheets for die cutting to suit many different applications.

Electrically conductive FoF and foams, both of which are available from Parker Chomerics, provide very low compression force because they are soft and allow for a large deflection range, which means they will not damage fragile electrical components within data centres and servers.

Play it cool

Among further data centre challenges is the excessive heat generated by servers and associated devices that operate continuously. Effective heat management is vital because high temperatures can lead to reduced performance and even equipment failure. Ventilation openings are frequently used for the dissipation of heat, either by flowing cooling air into the enclosure or providing an exhaust outlet for hot air. However, despite their crucial role in preventing device overheating, these openings introduce another challenge by providing a pathway for EMI to be emitted from or into the enclosed electronic assembly.

A common pick for enclosure chassis are honeycomb vent panels, which serve as high-performance yet economical solutions to EMI and airflow issues. Important selection criteria include EMI attenuation values, airflow rates, corrosion prevention, durability and flame resistance. Honeycomb vent panels also offer an incredible amount of customisation, including frame adjustments to ensure proper mating with the chassis.

For applications where maximum EMI protection and heat dissipation are necessary for long-term performance within electronic enclosures, fully shielded vent panels provide the answer. This vent type is ideal for ready-to-mount applications, where the addition of a compressed gasket along the vent seam supports ultimate EMI shielding.

A further option in low-clearance or space-critical applications are slim-design vent panels constructed of expanded aluminium or Monel® (nickel-copper alloy) foil rather than conventional honeycomb.

Making the grade

High-quality EMI shielding products can only perform their roles if they have the backing of a reliable manufacturing process. Parker Chomerics takes a global approach to production that is not solely reliant on a single manufacturing plant. With multiple production facilities across different countries, the company can offer the same high-quality products from two or more locations, enabling flexibility, fast delivery and security of supply as demand for these innovative EMI shielding solutions continues to grow.

Today, cloud deployment, the rollout of 5G and various bandwidth-hungry applications are overseeing the construction of more and more data centres. Network system manufacturers must therefore think carefully about EMI. After all, shielded data centres act as a countermeasure against EMI-impeded performance and security issues.

As always, prevention is better than cure. Design engineers need to anticipate EMI in the project’s intended environment to prompt the inclusion of optimal protection. Any failure on this part can lead to extensive problems further down the line, with last minute changes and additions proving expensive, not just in financial terms, but also in time and reputation.